The apparel industry has always been defined by creativity, fast-changing consumer demands, and global supply chains. But as the world moves toward digital-first operations, manufacturers face mounting challenges—rising costs, shrinking timelines, sustainability pressures, and heightened consumer expectations for personalization. To remain competitive, apparel manufacturers need more than just basic digital solutions. The next era is being shaped by a powerful fusion of ERP for Apparel Manufacturing, AI-driven decision-making, and the Internet of Things (IoT).

This is not just about digitization—it’s about transformation. From capacity planning for garment factories to AI-assisted supplier selection, the future of apparel manufacturing ERP software lies in intelligent automation and data-driven innovation. In this blog, we explore how AI and IoT are redefining ERP, MES, sourcing, and PLM for fashion manufacturers, and what this means for the future of global apparel production.

Global apparel manufacturing is undergoing a seismic shift. Several factors are driving companies to look beyond traditional ERP tools:

Traditional ERP systems built only for transactional control can no longer provide the agility or intelligence needed. Instead, the future calls for Apparel Manufacturing ERP Softwarethat integrates AI, IoT, MES, and PLM into one seamless digital ecosystem.

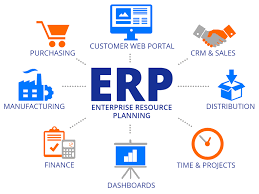

ERP Software for Fashion Manufacturers has always been the backbone of business operations, ensuring financial accuracy, material planning, and production workflows. But in the era of Industry 4.0, ERP systems are no longer just administrative—they are strategic.

Modern ERP for Apparel Manufacturing links multiple stakeholders: designers, manufacturers, suppliers, customers, and compliance teams. This single source of truth powers:

By combining ERP fundamentals with AI and IoT, apparel manufacturers are moving from reactive operations to predictive, proactive ecosystems.

Artificial Intelligence is the game-changer transforming every layer of apparel production. When embedded within apparel manufacturing ERP software, AI enhances decision-making, automates repetitive processes, and unlocks new predictive capabilities.

Traditionally, supplier selection was based on cost and availability. But in today’s world, brands need deeper insights into compliance, quality, delivery reliability, and sustainability. An AI Supplier Selection Tool for Apparel leverages data such as:

By analyzing these complex datasets, the AI tool recommends the most reliable, ethical, and cost-effective suppliers—helping apparel companies build resilient supply chains.

End-to-end visibility has become non-negotiable. An AI Supply Chain Platform allows apparel brands to anticipate delays, balance demand-supply mismatches, and optimize logistics in real-time. Predictive analytics enable early warnings on inventory shortages, while prescriptive AI suggests corrective actions such as sourcing from alternate vendors or redirecting shipments.

This capability not only reduces disruptions but also empowers sustainable choices, such as selecting the lowest-carbon shipping routes.

If AI is the brain, IoT acts as the eyes and ears of modern apparel production. From sewing floors to global warehouses, IoT sensors connect every process into the ERP system, ensuring real-time visibility.

Key applications include:

The integration of IoT data directly into MES for Apparel Manufacturing allows unprecedented transparency and agility—making it possible to reduce downtime, balance capacity loads, and react instantly when operations deviate from plan.

For years, MES for Apparel Manufacturing has been the crucial link between ERP’s long-term planning and the factory’s day-to-day execution. The future, however, lies in merging MES functionalities directly into ERP systems.

With ERP-MES integration, manufacturers move from static planning to agile manufacturing, aligning fast fashion schedules with flexible execution.

Modern fashion cycles depend on speed and collaboration. This is where PLM Software for Fashion comes into play. When seamlessly integrated within Apparel Manufacturing ERP Software, PLM provides:

By bridging creative design with manufacturing realities, ERP-PLM integration ensures innovation is both rapid and practical.

Sourcing is no longer just about finding the cheapest raw material. With rising sustainability requirements, compliance checks, and shifting global trade policies, sourcing has evolved into a strategic differentiator.

Apparel Sourcing Software embedded into ERP systems ensures:

When combined with AI supplier selection tools, sourcing software helps apparel manufacturers forge resilient supply chains that thrive even under global uncertainty.

The future of apparel manufacturing will be defined by fully connected factories, where ERP, PLM, MES, AI, and IoT converge into one ecosystem. Here’s what’s coming:

The integration of AI and IoT into ERP Software for Fashion Manufacturers unlocks measurable benefits:

The apparel industry is at the threshold of a new digital era. Simply digitizing processes will no longer be sufficient; the competitive advantage will belong to those embracing AI and IoT as integral components of their Apparel Manufacturing ERP Software. By investing in ERP for Apparel Manufacturing solutions that integrate MES, PLM, sourcing, and AI-powered supply chain platforms, apparel factories will not only meet consumer expectations for speed and sustainability but also future-proof themselves against global volatility.

In the future, the most successful apparel manufacturers will be the ones who can bridge creativity with technology—delivering fashion that is fast, sustainable, and intelligent.