Managing apparel manufacturing across multiple locations is one of the most complex challenges fashion businesses face today. With thousands of SKUs, diverse raw material requirements, fluctuating consumer demand, and global sourcing dependencies, traditional systems like spreadsheets or standalone software quickly become inadequate. To stay competitive, manufacturers are increasingly turning to ERP for apparel manufacturing—a robust digital backbone that integrates production planning, sourcing, inventory visibility, and product lifecycle management into one unified platform.

This blog explores how ERP systems designed specifically for apparel help manufacturers overcome multi-location inventory challenges and SKU complexity, while also enabling smarter planning, sourcing, and production execution.

The apparel industry is uniquely complex compared to other manufacturing sectors:

These factors often result in inconsistent stock levels, inventory leakage, poor demand fulfillment, and obsolescence. That’s where apparel manufacturing ERP software delivers real impact.

SKU proliferation is unavoidable in fashion. For example, if a single shirt design is offered in 5 colors and 6 sizes, that’s 30 SKUs from one item. Multiply that by hundreds of styles each season, and apparel businesses deal with thousands of SKUs to track and manage.

Coupled with multi-location production and distribution centers, apparel companies often encounter:

ERP systems built for apparel are uniquely designed to tackle these challenges with advanced modules for capacity planning, sourcing, scheduling, and inventory optimization.

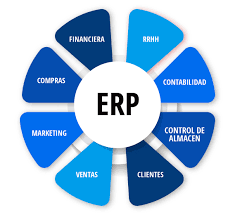

ERP software for fashion manufacturers provides an end-to-end solution to manage supply chains, production, and distribution. Unlike generic ERP systems, apparel manufacturing ERP software incorporates industry-specific functionality like size-color matrices, style-based planning, batch-level fabric tracking, and integration with PLM and MES systems.

This unified approach ensures efficiency and agility, positioning apparel companies to handle high-volume operations without compromising speed or accuracy.

ERP helps fashion companies create end-to-end visibility across multiple warehouses, factories, and distribution centers.

With ERP integration, apparel manufacturers reduce carrying costs, minimize stockouts, and improve service levels for both retail and e-commerce channels.

ERP systems use SKU classification and size-color matrix management to simplify complexity. Rather than handling each SKU as a separate entity, the ERP system groups them under product hierarchies linked to styles, fabrics, and colors.

This reduces data complexity for:

With barcoding and RFID integration, ERP ensures accuracy in SKU-level tracking across the value chain.

A growing number of fashion manufacturers now connect ERP with MES for apparel manufacturing. MES (Manufacturing Execution System) adds granular shop-floor visibility:

With MES integrated into ERP, apparel manufacturers optimize workforce productivity, reduce wastage, and ensure faster decision-making.

While ERP and MES focus on supply chain and production execution, PLM software for fashion manages product innovation and development at the design stage.

By combining PLM and ERP, fashion companies gain a seamless design-to-delivery pipeline that handles both creativity and operational efficiency.

Artificial intelligence is transforming ERP platforms into AI supply chain platforms for apparel. These tools leverage machine learning to predict outcomes and automate decision-making.

These AI-driven modules ensure apparel manufacturers reduce costs, mitigate risks, and improve agility in volatile markets.

Capacity planning is one of the hardest tasks in apparel. Poor planning leads to idle machines, overtime costs, delayed shipments, and cancelled orders.

ERP systems come with capacity planning for garment factory modules that:

With an intelligent production scheduling tool for apparel, ERP ensures efficient utilization of resources and on-time deliveries.

Sourcing fabric, trims, and accessories is fundamental in fashion manufacturing. Apparel sourcing software integrated within ERP digitalizes vendor management and procurement.

Features include:

When paired with the AI supplier selection tool for apparel, sourcing managers get data-backed recommendations, reducing risks of delays or non-compliance.

Implementing ERP software for fashion manufacturers unlocks measurable advantages:

As the industry moves toward digital-first ecosystems, the future of ERP for apparel manufacturing lies in AI-based automation and cloud-native platforms. Cloud ERP provides scalability and flexibility for global apparel businesses, while AI-driven modules ensure predictive planning and intelligent supply chain orchestration.

An integrated digital ecosystem connecting ERP, MES, and PLM will be the new standard, creating an end-to-end solution from design to delivery.

Managing multi-location inventory and complex SKU structures is central to success in apparel manufacturing. Traditional management methods fail under such complexity, but apparel manufacturing ERP software provides the integration and intelligence required to excel. From capacity planning in garment factories to AI-powered supplier selection tools and production scheduling, ERP enables apparel companies to optimize operations, cut costs, and meet fast-changing consumer demand.

By leveraging ERP alongside MES, PLM, and AI-driven platforms, apparel businesses can achieve the agility and efficiency necessary to dominate the future of fashion manufacturing.